Book a demo

The Edge is an innovative building located in Amsterdam. It was designed by OMA architect Ron Bakker and has become a revolution in sustainable and energy efficient building. The building covers an area of 40,000 m2 and it is entirely controlled by the IoT, which optimises energy consumption by regulating every element of the building from lighting to heating.

The Edge has been enabled with a Smart Building System. Occupancy, routing, heating and ventilation are all controlled by the IoT system, giving the building an unprecedented 98.36% energy efficiency.

The IoT system, installed by the Dutch company Dell, is made up of 28,000 connected sensors that regulate the operation of all devices, ensuring uniformity of temperature and lighting conditions and keeping energy consumption to the lowest level/minimum.

The Edge's designers have prioritized the use of natural light and the building has large exterior windows that allow diffused light to enter the building. The aim is to reduce the use of artificial light and save energy. The Edge also uses an underground heating system for temperature management, where hot and cold water is supplied through pipes, helping to maintain the ideal temperature while reducing energy consumption.

Energy consumption analyzes show that the building was able to reduce overall energy costs by 70%.

credit: Edge.tech

The Edge received LEED Platinum certification from the US Green Building Council in 2016, which recognizes a building's environmental credentials. The building design focused on employee comfort and facilities were installed to meet these standards. It has become a model for sustainable, energy-efficient homes that combine human comfort with minimal environmental impact.

Using innovative technologies, applying new green designs and materials, and focusing on occupant comfort, The Edge is a fantastic example of how buildings can be made sustainable and energy efficient. The building's levels of energy efficiency, technological innovation and ergonomic design have made it a significant benchmark for environmentalism.

A real example of how it is possible to reshape our notions of energy and resource management in building construction.

Discover how IoT technology can revolutionize your business operations and increase your efficiency. Contact Us and explore our range of IoT solutions that can help you enhance your operations and reduce your energy consumption. Let us help you transform your business and build a sustainable future.

Fill out the form at the end of the page to request information on products or partnerships.

Health, disease and aging affect everyone. Everyone invests in their well-being, for prevention and treatment. Investments are based on data, which are collected at home, in hospitals, clinical research laboratories and mobile devices. For security and privacy reasons, the data is kept separately.

Federated learning offers the possibility to address these issues, both for the general population with features common to all and for the individual in the rare or unusual case.

The variability of applications and configurations is another strong point of Federated Learning offered by Sensoworks and Frontiere:

Hospitals could use federated learning models to predict the likelihood of an individual patient developing a disease or contracting an infection after being admitted. This could help doctors make better decisions about how best to treat each patient based on their specific needs. Additionally, these predictions could be used by other organizations that work with hospital patients (such as insurance companies) in order to provide better coverage options for those who need it most.

Another area where federated learning can benefit healthcare is by helping us understand diseases like cancer or Alzheimer's disease at the genetic level better. Using federated learning models on DNA samples collected from thousands of people suffering from these conditions, researchers can gain insight into which factors contribute most to the development of these diseases.

Federated learning provides interoperability gains that positively impact healthcare professionals quickly accessing a patient’s medical information even if they are not within the organization’s internal systems (e.g., patients visiting from another country), and applying analytics. High quality medical decisions could be ensured regardless of the patient's treatment location and local knowledge of the disease. Physicians can augment their expertise with expert knowledge from other institutions, ensuring consistency of diagnoses that would not be possible otherwise, improving the effectiveness of patient care and enabling greater collaboration in the healthcare sector.

Federated learning has been used in medical research because it allows researchers to create large sets of patient data that they can then use as part of their research efforts without needing direct access to any individual's private health information. It also allows researchers who may not have access to certain medical records or resources (such as patients' genetic information) to instead access those same resources through other researchers' databases. This prevents privacy breaches while still allowing researchers access to sufficient information and insights.

As healthcare and clinical-data is scattered, gathering a data set that is complete enough to track rare cases involves combining data from various data silos. The practical challenges of any single site lacking adequate and sufficient data for rare adverse drug reaction detection and prediction, can be addressed. Likewise federated learning can assist in reaching the cohort sizes for orphan/rare disease studies and ensuring ethnic genomic diversity.

Precision medicine is a growing field in healthcare. A precision medicine study is an experimental study that uses personal data to develop a personalized treatment plan for an individual patient. The aim of these studies is to direct the treatment based on an individual person's unique genetic profile and medical history. Federated learning can be used to predict things like disease progression or patient outcomes, but it can also be used to predict patient responses to medications or other treatments. Using federated learning to analyze large amounts of patient data could help researchers identify new approaches to treating diseases like cancer and Alzheimer's at the molecular level, which could lead to more personalized treatments for patients. With access to large data sets, more precise drugs can be developed in an accelerated way.

Home health monitoring has attracted great attention for aging populations around the world. With abundant user health data being accessed by Internet of Things (IoT) devices, smart healthcare has seen many success stories. A personalized wearable device is used to collect, store and send health-related metrics, and can make medical recommendations for unusual health conditions. Nursing homes can offer specialized and constant care to the elderly. In these centers, remote health monitoring and recommendations can offer better services at reduced costs.

By unifying large data sets, new levels of well-being are offered at affordable costs.

Contact: dr. Remco Foppen

Fill out the form at the end of the page to request information on products or partnerships.

Waste management is a significant challenge for many cities worldwide. The amount of waste produced is constantly increasing, then an organised and efficient collection must be necessarily implemented. It must be efficient in order to provide timely and efficient service to citizens, and must aim to be more sustainable in terms of both environmental impact and the costs of management itself.

One of the biggest issue in waste management is the lack of information related to the waste flow. Often, waste managers do not have a complete understanding of the amounts and types of waste produced in a delimited area, making it difficult to efficiently plan the waste collection and disposal.

Moreover, many waste management systems are still manual and require a lot of time and human intervention to be performed correctly. This leads to higher costs and low efficiency in waste management.

All of this is primarily due to the presence of outdated infrastructure. Many waste management facilities are old and were not designed to support IoT technology. This makes it difficult to implement a smart picking system into existing infrastructure.

IoT (Internet of Things) technology is transforming many industries, and waste management is not an exception. IoT technology allows real-time data collection on the waste produced in a given area, and this data can be used to improve the management of the process. Here's how smart picking can improve waste management:

IoT can thus improve waste management by providing precise and real-time information on the waste produced in a given area, allowing for more efficient waste collection and disposal planning, reducing operational costs, and increasing the recycling rate.

Here are 4 brief examples showing the effectiveness of an IoT solution:

Fill out the form at the end of the page to request information on products or partnerships.

Smart manufacturing, or the connected factory, is a central concept in Industry 4.0 and represents an evolution of the traditional approach to production. Through the use of advanced technologies, sensors, and IoT devices, companies can achieve greater efficiency and flexibility in production, allowing them to adapt to market demands more quickly and efficiently.

The intelligent factory represents the endpoint of companies' digital transformation. The goal is to create a highly interconnected and flexible work environment, where machines, production systems, and IoT devices work together to optimise production and reduce costs.

The connected factory is based on three pillars: connectivity, digitalization, and automation.

Smart manufacturing is based on the interconnection of production systems and IoT devices. These devices can include sensors, actuators, motors, machinery, robots, mobile devices, and other elements that can collect information about production activities. This data is then sent to a cloud platform, where it can be analyzed and used to make informed decisions.

The interconnection of IoT devices also enables real-time monitoring and control of production activities. For example, an AI-based IoT platform can analyze data from sensors in real-time and identify any anomalies in production. The system can then adjust production accordingly, reducing machine downtime and improving product quality.

The use of advanced technologies such as AI, machine learning, and deep learning can lead to significant improvements in productivity and product quality. For example, an AI-based IoT platform can analyze large amounts of data in real-time, identify issues, and suggest solutions to improve production. Additionally, machine learning can be used to predict machine failures, reduce machine downtime, and prevent production interruptions.

Automation is another important feature of Smart manufacturing. Automation can be used to automate production activities and reduce personnel involvement in repetitive, low-value tasks. This can free up personnel to perform higher value-added activities such as design, innovation, and system maintenance.

The adoption of these technologies can lead to increased competitiveness for the company in the market, through reduced costs, increased productivity, and greater flexibility.

Many companies have already adopted Smart manufacturing and are achieving remarkable results.

For example, the German company Siemens has implemented a flexible production system that allows for quick and customized production of products requested by customers.

The American company General Electric has adopted a remote monitoring system based on IoT, which allows for real-time monitoring of machine performance and prevention of potential breakdowns.

According to a study conducted by McKinsey, the adoption of advanced technologies such as artificial intelligence and automation can lead to a 20-30% increase in productivity and a 10-20% reduction in costs.

Fill out the form at the end of the page to request information on products or partnerships.

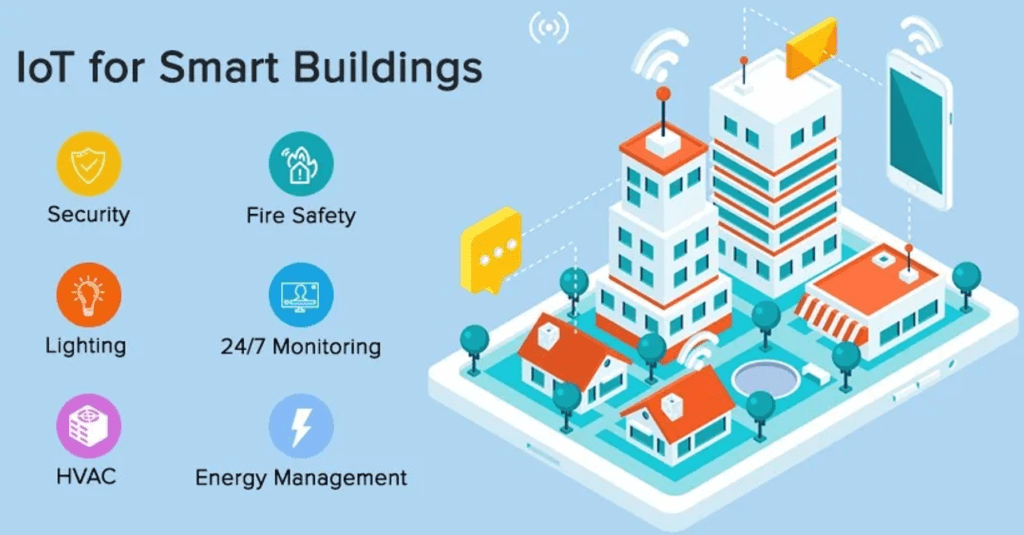

A Smart Building is a structure that uses advanced technology to optimize its performance and improve the comfort, safety, and productivity of its occupants. They use a variety of sensors, devices, and systems to collect data from the building's facilities and environment and use this data to control and automate building functions such as heating, cooling, lighting and security.

One of the key components of a smart building is the use of an Internet of Things (IoT) platform, which serves as a central hub for data collection (monitor), analysis of building system data (predict) and for controlling and automating building functions (control).

IoT platforms often use artificial intelligence (AI) and machine learning algorithms to analyze data and identify patterns and trends, which can be used to optimize building performance and make data-driven decisions.

Smart buildings can offer a wide range of benefits, such as increased energy efficiency, improved comfort and productivity for occupants, enhanced security and reduced maintenance costs. They also have the potential to play an important role in addressing global sustainability and environmental challenges.

After defining what a Smart Building is, we list the important aspects to consider based on our experience applied to the projects we have developed.

An intelligent IoT platform can address the issues of a Smart Building by providing advanced automation and analytics capabilities, therefore:

An intelligent IoT platform can provide several benefits in terms of cost reduction, sustainability, and social impact:

The exact percentage of cost reduction, energy savings, and other benefits depends on many factors such as the specific implementation and goals.

There are several studies from authoritative sources that have estimated the benefits under certain conditions.

For example, according to a study by the Rocky Mountain Institute, smart building projects can save building owners up to 20-30% on energy costs and up to 15-20% on maintenance costs.

The National Renewable Energy Laboratory (NREL) reported in a study that, on average, commercial buildings can achieve energy savings of up to 20% by implementing IoT-enabled building automation systems.

A study by the McKinsey Global Institute reported that IoT-enabled building systems can reduce energy consumption by 10-20% and improve overall building efficiency by 5-15%.

Fill out the form at the end of the page to request information on products or partnerships.

Public lighting is a relevant - and sometimes taken for granted - component of urban life, fundamental in terms of safety and comfort, but it is also used as an aesthetic element to adorn our cities by highlighting, for example, the historical monuments. However, up until now, its management and maintenance were often complex and expensive due to manual management that did not permit complete control on parameters such as consumption, faults, and various issues.

Now, thanks to IoT technology, public lighting is undergoing a revolutionary evolution that is changing the way we see and interact with our urban environment. With IoT, cities can become safer, more efficient, and more attractive, creating a “brighter” future for all of us.

The disconnected lighting can lead to various problems in the management of city public lighting:

IoT offers a solution to the problems listed above, thanks to its ability to gather together all the data coming from the various components of public lighting systems in real-time, allowing a more centralised and efficient management and a greater optimization of costs. For example, local authorities can monitor and control in real time public lighting systems remotely, identify any problems and intervene quickly to resolve them. Furthermore, IoT allows for better energy management, through automatic regulation of the light intensity according to needs

Therefore, the advantages in summary are:

Energy savings and cost reduction, of course, varies depending on several factors such as the size of the city or the amount of monuments to be illuminated. But some studies have shown that the adoption of connected public lighting systems can lead to an average energy savings of 40-60% and a cost reduction of up to 50% or even more in particular conditions.

In conclusion, connected public lighting represents an important step forward in managing the city and the lives of its residents. With its ability to improve safety, energy efficiency, and the comfort of public spaces, the adoption of connected lighting systems with IoT software solutions can bring a series of benefits to cities and their residents. Additionally, the adoption of connected lighting systems can help reduce environmental impact, improve the quality of life for citizens, and promote sustainable development of cities.

Fill out the form at the end of the page to request information on products or partnerships.

As the digitization process of enterprises advances, the need to protect sensitive information and data is also becoming more pressing. In fact, digital transformation is not just about mere technological advancement: it is also about constant attention to the development of effective strategies to safeguard smart networks from potential cyber-attacks. In this sense, cybersecurity assumes primary importance and must be among the priorities of a company that really wants to call itself innovative and open to the future.

Speaking of 2022 cybersecurity-themed trends, Gartner calculated that by 2025, 45 percent of companies will have been victims of supply chain cyber-attacks. However, companies that adopt mesh architecture will be able to reduce the impact of individual attacks by up to 90%.

In this context, it is more critical than ever for companies to have frameworks that identify hacker attacks, protect technology systems, and detect and neutralize threats. An Industrial Internet of Things (I-IoT) system, in addition to optimizing the production process by making it more efficient, should also include strict security controls. The basic principles of cybersecurity (the so-called "CIA" criteria, Confidentiality, Integrity, Availability) are as valid as ever in an Industry 4.0 context in which, according to Niccolò De Carlo, CEO of Sensoworks, the best approach to create an effective and functional protection system is definitely a holistic one. In fact, attention to data collection, storage, and use must be part of a broader and more comprehensive cybersecurity perspective.

In light of an industrial scenario so fertile with digital opportunities and innovations, Sensoworks stands as a partner able to offer targeted solutions to enable companies to preside over the digital transition and, at the same time, ensure that their data is always adequately protected.

Indeed, security protocols and technologies are fundamental to Sensoworks: in addition to collecting, monitoring, and interpreting data from sensors connected to machinery and infrastructure, the platform is easily configured to best preserve sensitive information.

In addition, the entire production process is protected through blockchain technology, a shared structure that cannot be modified within which data is entered that, once entered, will not be tweaked or deleted— a guarantee of the correct information that is essential to ensure all-around cybersecurity.

We have seen how developing effective strategies to protect data and networks from potential cyber breaches is now imperative. At the same time, however, as Sensoworks CEO De Carlo reminds us, it is also necessary to study effective strategies for the physical security of the infrastructure.

An example of an architecture that involves both physical and technological structure might be an integrated water system. Here, through cyber-infrastructures such as smart water networks, IoT, data-science techniques, augmented intelligence, and, indeed, blockchain, it is possible to make more informed decisions in real-time precisely because of sensors and instrumentation that are in charge of securely collecting and transmitting data.

Thus, one can see how knowledge and data security act to support business decisions, while also giving greater awareness of water consumption and value.

"We are reaching 3.5 billion connected devices globally. Our use of most of these devices to date plays a strategic role for our country," De Carlo points out.

"Let's think for a moment about road infrastructure, power generation infrastructure. They are increasingly connected and need to be preserved from any kind of risk. Thanks to technologies like Sensoworks', it is possible to identify if a device, a sensor, a device is not working properly or if it has been intentionally tampered with."

Stay tuned to our social channels so you don't miss any upcoming updates.

Contact Eleonora Stragliotto, Head of Sales, to learn more about how the Sensoworks platform protects sensitive information and data.

Logistics, supply chain, vehicle fleets and various assets that make up the vital chain of a business all need extreme caution and attention to avoid undesired events such as malfunctions, breakdowns, loss, etc. Not to mention the cost of reparations, deployment, inspections and all the effort wasted in reorganizing all the assets to cover the hole in the chain, even if temporarily.

When speaking of asset management, hence, businesses are faced with multiple, hard challenges:

Companies with a large number of assets or a certain scale of operations have always had to monitor and control the performance of their assets. Enterprise Asset Management (EAM), indeed, might not be a new concept, but the technology and the application methods have changed much in the last years.

“Traditionally”, assets - and asset management activities - were all considered independently. Each had its performance, values, efficiency and the final results would then make up the whole of the asset grid, up to the provided services. However, this not only brought to the systemic creation of data silos - which hinder scalability and overall development - but also to an erroneous conception of monitoring and asset performance.

Good asset management, instead, should always look at the company resources and performance as parts of a whole, each with a certain relevance, for each is a critical gear in a complex machine.

To have multiple solutions to tackle the several problems with the management of the various assets would be equally counterproductive and decentralizing. That is why Sensoworks came up with one solution that could integrate all the potential answers to the many problems businesses face on a daily basis with their asset management operations.

Senso Asset is the central component of Sensoworks’s IoT Asset Management solution It allows companies to manage the entire asset’s life cycle, from procurement and installation to management and maintenance, until its disposal.

IoT technology has an unprecedented potential to simplify and cut the costs. From automation to detailed information based on data, IoT can increase current resources and maximize the efficiency of the workforce. However, we still face many challenges in IoT adoption. We need to introduce tools and organic asset monitoring methodologies, with a data-driven decision-making approach.

This way, management becomes fully automated, enhancing the efficiency of the whole value chain. Spread implementation of these systems simplifies the way producers, suppliers and storehouse managers work. No more from a data silos perspective. This means:

Moreover, workflow automation also means that the user gets notified immediately when an event occurs or an alarm goes off - for instance, maybe because certain values exceeded the given threshold. Alarms, in particular, are extremely intuitive to manage on Senso Asset. The location of the event is shown on a map, giving the user the possibility to click on it and check all the necessary information to take action and intervene immediately on the emergency.

The predictive analysis tool helps to identify the main cause of a problem and to work on damage control, managing mistakes in advance. The production line will be provided with more data, which allow for higher visibility and to undergo complex scenarios for a stronger management system.

In brief, IoT devices’ automation and data gathering skills make the work environment more efficient. They value the various measurements and suggest the best decisions based on data and predictions.

Senso Asset is designed to be fully integrated into Sensoworks IoT platform for complex IoT scenarios, for both on-premise and cloud infrastructures. The gathered and processed data are shown to the user both in a dashboard and in the form of reports, with the possibility to encrypt data on a centralized blockchain.

Moreover, Senso Asset moves with a microservices approach, which helps both the platform and the customer to implement whatever necessary modification to their assets and services without compromising the entirety of the activity.

The platform is open source to give the customer the max flexibility in terms of product adoption. We want to empower our users with the opportunity to customize their experience and make their own decisions when it comes to collecting and processing data. That’s why Senso Asset can also be connected to data and devices the customer already possesses and is designed with an API-first approach. In case of specific needs, we can also provide our Edge Gateway to collect data from sensors and even provide our customers with sensors manufactured by our trusted partners.

However, we are a fan of an agnostic approach when it comes to monitoring and controlling critical assets: in the solutions we design, we are willing to implement whatever protocol our customers need. Specifically, Sensoworks’s platform supports the main standards and protocols in the IoT industry:

As we saw, one of the main challenges for the management of company assets is the need for a specific vision in the monitoring of the single resources. The dynamicity and globality of today’s markets, instead, pushes companies to strive to be more efficient, which can be achieved only thanks to an organic and holistic management of all the assets.

On the other hand, in the last years, software solutions and connectivity developed exponentially - and still are. This allows us to have solutions like Senso Asset, for an all-in-one management of any asset and the flexibility to integrate old standards, but also to change due to technological developments in the future.

The complexity of the problems and the diversity of the available solutions also calls for an important initial moment where the company (usually, with specialized consultants) has to analyze its environment and goals. Thus, it has to take fundamental decisions for its technological infrastructure.

If your company manages complex assets too and if you want to discover how it can benefit from new available solutions, we would love to arrange a virtual meeting. We will provide you with all the necessary information and, if necessary, we will prepare a specific demo for your company.

Write to us with a brief description of your needs.

It has been over a decade since Internet of Things was first coined by Kevin Ashton. Since then, it has expanded alongside a growing technological hub spanning a diverse set of industries. In many ways it makes our everyday life more efficient, bridging the gap between physical objects with the collection and sharing of data on the internet.

Internet of Things has paved the way forward for objects to interact with each other without the need of management by people. Decisions are taken in real time, supported by data that help you detect any changes happening in the surroundings.

[rml_read_more]

The potential of this sector within urban cities is increasingly evident and there are many realities ready to invest in this type of innovation. Debates have run high as to the potential this technological age may bring forward. However, one thing we know for sure is that it is enabling opportunities in areas we would have never imagined.

Its impact expanded into developing countries, where it has the capacity of changing existing processes and improve efficiency in sectors in need of new solutions to a variety of challenges. By providing a cost-efficient model for enhancing the development in different processing mechanisms through the improvement of various projects in the research, monitoring, and evaluation stages, there are higher chances for these countries to live in more sustainable environments.

Developing countries have always faced the challenges that come with the distribution of water and the improvement of sanitary conditions. IoT technologies created a path in which different countries are addressing the same problems in innovative ways. The startup CityTaps began an experiment in Niamey, Niger, partnering with the local water utility struggling to afford to maintain, operate, and handle the barometers, which drives the costs high and hinders useful restorations.

Their solution was partnering with utilities and setting up a network of IoT systems supported by a Low Power Wide Area Network that allows the generator to create payments and detect malfunctions in real time. By leveraging data from the sensors, more accurate performances can result. The process works by having the consumer pre-pay for water services at home through a mobile device. In this way, it is easy for the consumer to pay any amount at any time, while the provider is guaranteed with the payment for the service delivery.

In India, we find Smarter Homes, a startup tackling water consumption with at-home monitoring systems. In response to a 2014 water crisis in Bengaluru following population growth, IBM’s IoT division collaborated with the Bengaluru Water Supply and Sewerage Board in forming a command center where they were able to track the water flow and pressure, while the IBM Intelligent Water Software alerts officials about any discrepancies in the system.

Healthcare in developing countries is another sector benefitting from the IoT innovations. Nexleaf Technology is improving health conditions by making the vaccination settings better via a wireless remote temperature monitoring system called Cold trace. The system sends storage temperature and power status to individuals through SMS whenever there are changes in the environment. IoT’s role is having the sensors in these containers monitor temperature, humidity, and light.

It also is a means for developing emergency response tactics when disasters strike these regions; where poor infrastructures and high population densities play a significant role in how the circumstances unfold.

Known for its susceptibility to earthquakes, Mexico uses an early warning system called SkyAlert that detects seismic activity 120 seconds before impact in accordance to the distance of the epicenter. Thus providing greater opportunity for people to take shelter before the earthquake hits.

Brazil launched a first of its kind state-of-the-art intelligence center in 2010, as a response to the fatal landslides that took place in the spring. Motion sensors generate data feeds on traffic, weather, police and medical services in real-time. Once the data is generated, anticipated problems are detected and defenses are set into place. If potential emergencies arise, citizens are alerted via sms and other media platforms. Those prone to at-risk areas receive a siren call for evacuation instruction.

With a new technological advancement happening in the developed world, and the impact that IoT has had in industries like agriculture and transportation, there are numerous applications where it can be of use in the developing worlds. Who knows? Maybe the Internet of Things is a possible solution to the processes needed for these countries to overcome these challenges.

For more information, please visit the link below to visit the World Economic Forum’s Guidebook to building a more sustainable society using the Internet of Things.